When quality or safety issues arise, rapid and effective troubleshooting is essential to protect consumers, maintain compliance, and minimise disruption. Phoenix Food Consultancy provides expert investigation and resolution support, getting to the root cause quickly and restoring confidence in your operations.

Issues in food production can occur at any stage, from raw material handling and processing to packaging, storage, or distribution. Whether it’s a contamination event, customer complaint, or unexplained non-conformance, identifying the root cause is critical to preventing recurrence and protecting your brand.

Troubleshooting requires a methodical, evidence-based approach. It may involve reviewing your ingredients, process parameters, cleaning protocols, documentation, and even personnel behaviours. Quick fixes may solve symptoms, but true resolution comes from identifying underlying causes.

Phoenix Food Consultancy offers comprehensive technical troubleshooting services to investigate, assess, and resolve issues that compromise food safety, quality, or compliance. We work discreetly, independently, and with minimal disruption to your operations.

Whether it’s a minor issue or a major incident, our troubleshooting service is built on technical insight, practical experience, and a calm, focused approach. We work closely with your team to ensure that problems are resolved quickly – and stay resolved.

We go beyond surface symptoms to uncover the true causes of quality and safety failures.

Practical investigations with process walkthroughs, data reviews, and staff engagement.

Comprehensive reports with findings, evidence, and next steps to support corrective action.

Years Experience

Tony Crilly BSc. (Hons) FIFST has led complex troubleshooting investigations across a wide range of food manufacturing environments. From microbiological contamination to allergen mislabelling, Tony’s experience allows him to rapidly assess problems, identify root causes, and develop corrective action plans that are practical, compliant, and effective.

With over 25 years in technical management, Tony understands the operational pressures businesses face during a crisis. He works calmly and discreetly alongside your team, restoring control, satisfying customer or regulatory demands, and helping your business move forward with confidence.

Robust HACCP systems to prevent issues before they occur and respond effectively when they do.

On-site audits and reviews to identify hygiene-related root causes of contamination.

Identify weaknesses before they result in failures through scheduled, objective audits.

Ensure compliance with legal and regulatory requirements during and after incident resolution.

Temporary support during incidents or crises to stabilise technical performance and compliance.

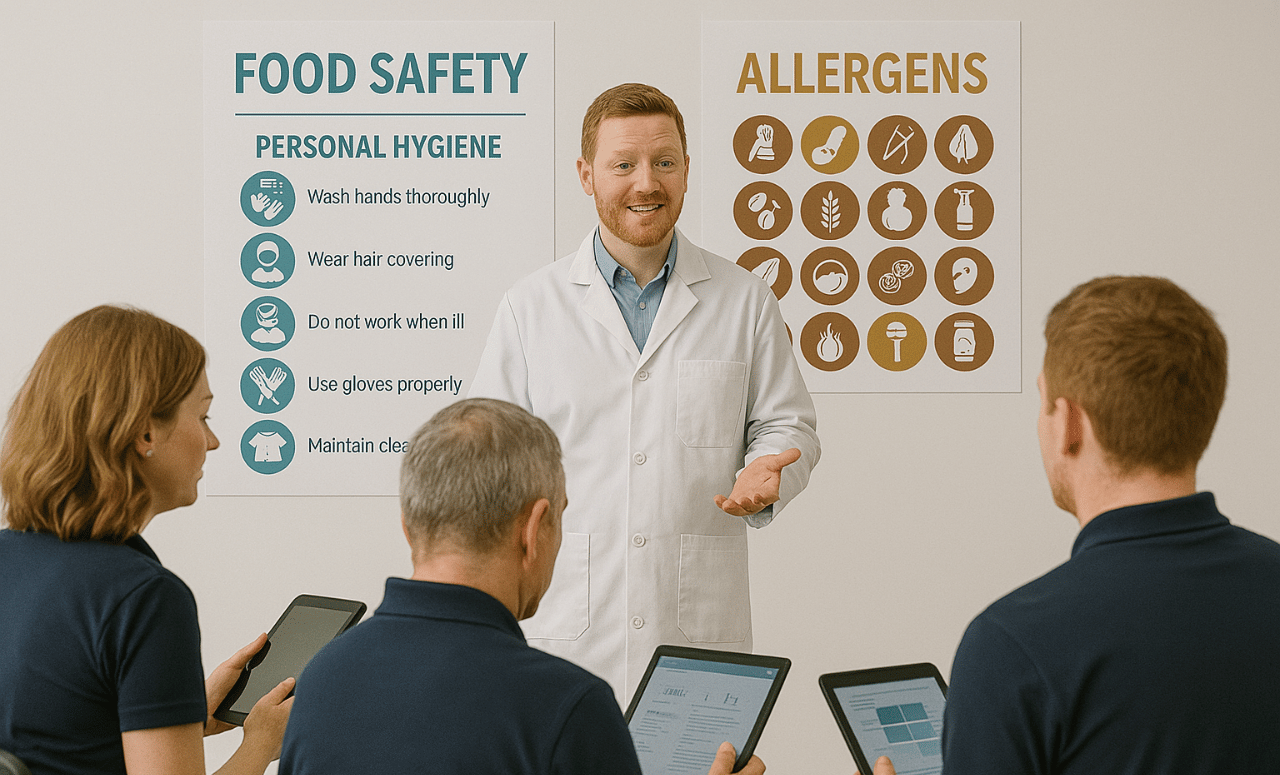

Upskill your team following an incident with refresher training on hygiene, HACCP, or QMS.

Phoenix Food Consultancy provides expert-led food safety and technical support to food businesses across the UK and Ireland.

Copyright © 2025 Phoenix Food Consultancy Ltd, All rights reserved. Built With ♥ By Just There